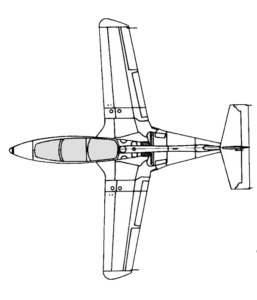

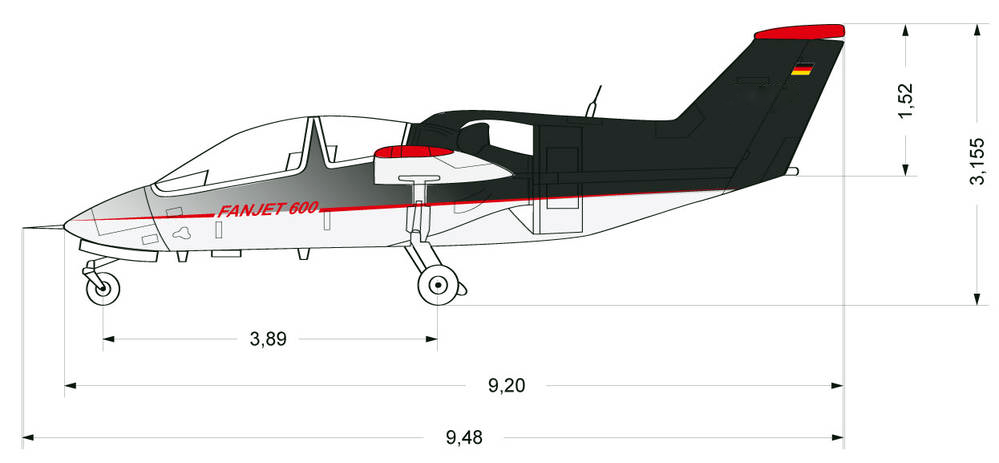

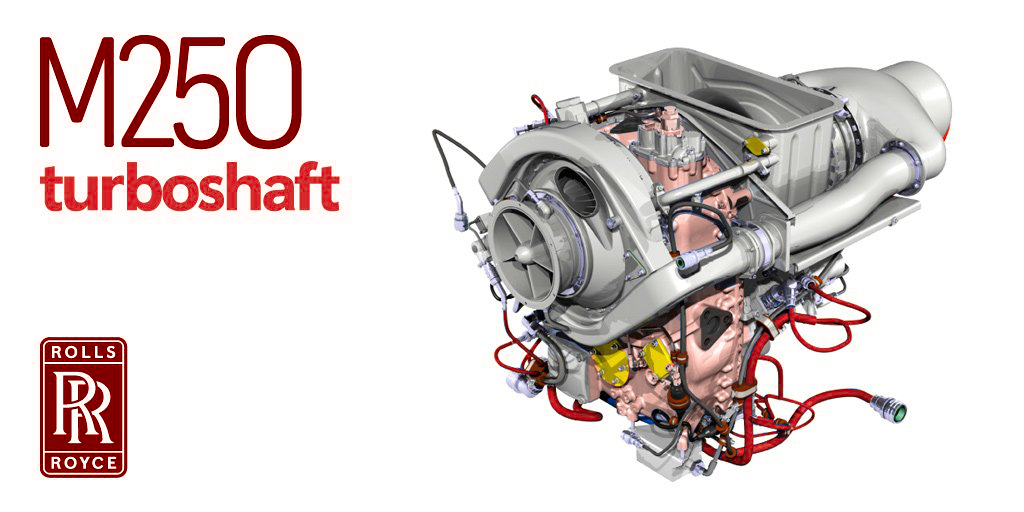

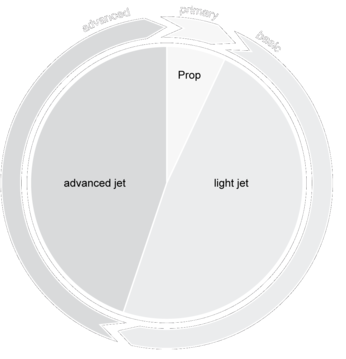

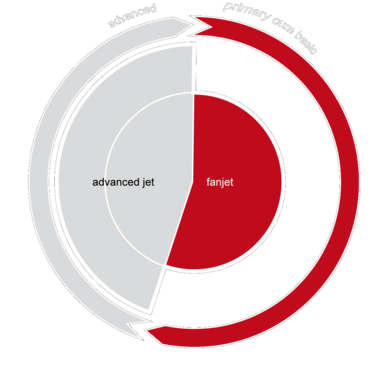

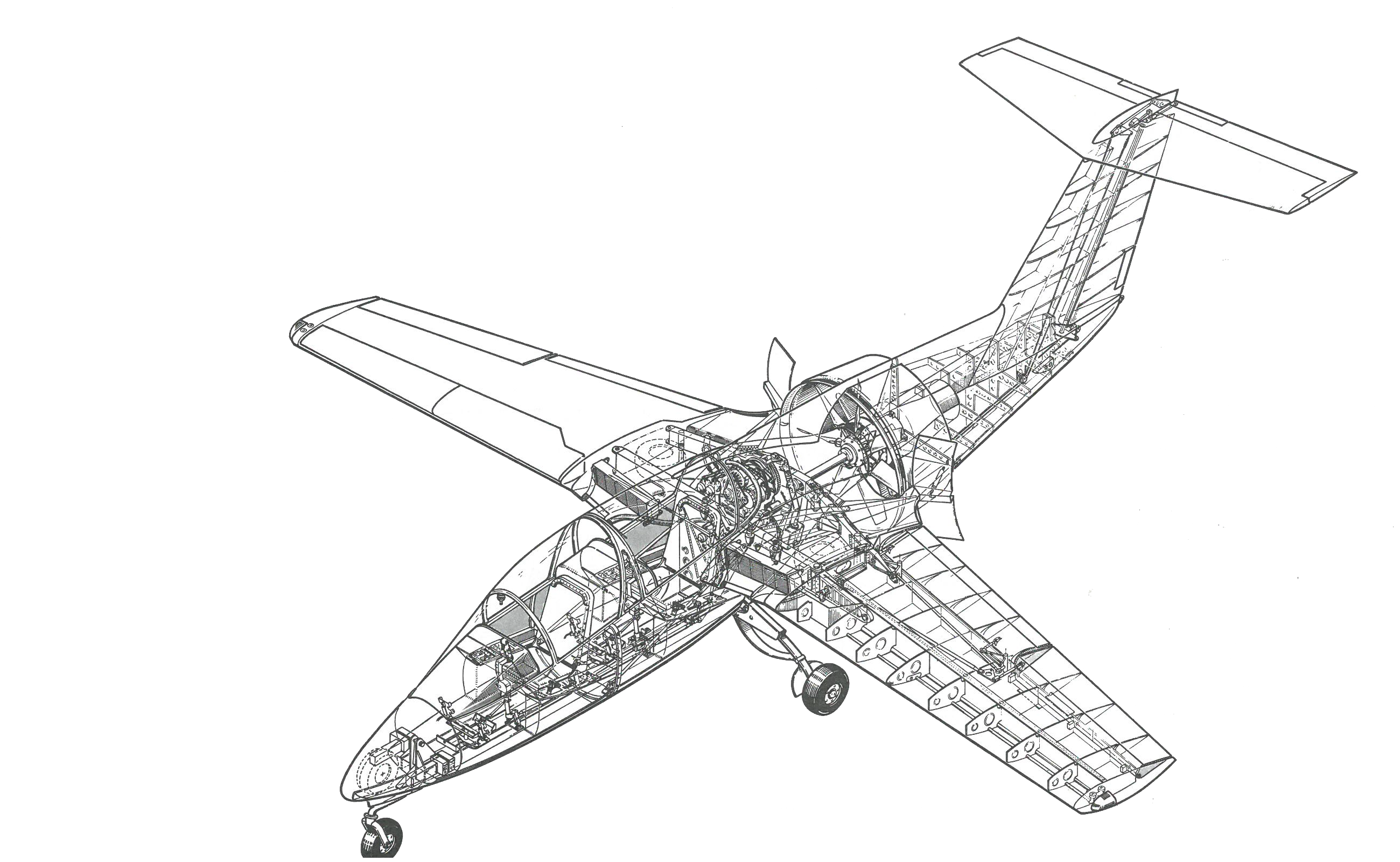

The FanJet 600 is an innovative, basic and advanced trainer with realistic jet like handling characteristics and has been fully certified. With its bypass fan engine positioned behind the rear cockpit the FanJet 600 will simulate the flight behavior of a basic jet aircraft and will make a significant handling difference to any turbo prop trainer in its class.

Compared to other jet trainers with turbo jet enginges , the FanJet 600 has much lower oporation costs (fuel consumption) of only to 20% -25% of turbo jet trainers. It can carry out all relevant maneuvers and provides a jet like environment.