Diese Website verwendet Cookies, damit wir dir die bestmögliche Benutzererfahrung bieten können. Cookie-Informationen werden in deinem Browser gespeichert und führen Funktionen aus, wie das Wiedererkennen von dir, wenn du auf unsere Website zurückkehrst, und hilft unserem Team zu verstehen, welche Abschnitte der Website für dich am interessantesten und nützlichsten sind.

FanJet Aviation GmbH aims to revive this unique German aircraft, the Fantrainer 600 and introduced it under the new name Fanjet 600.

In 2010, the company bought the documentation for design, test and certification for the original aircraft Fantrainer 600.

This was followed by the acquisition of tools and spare parts inventory.

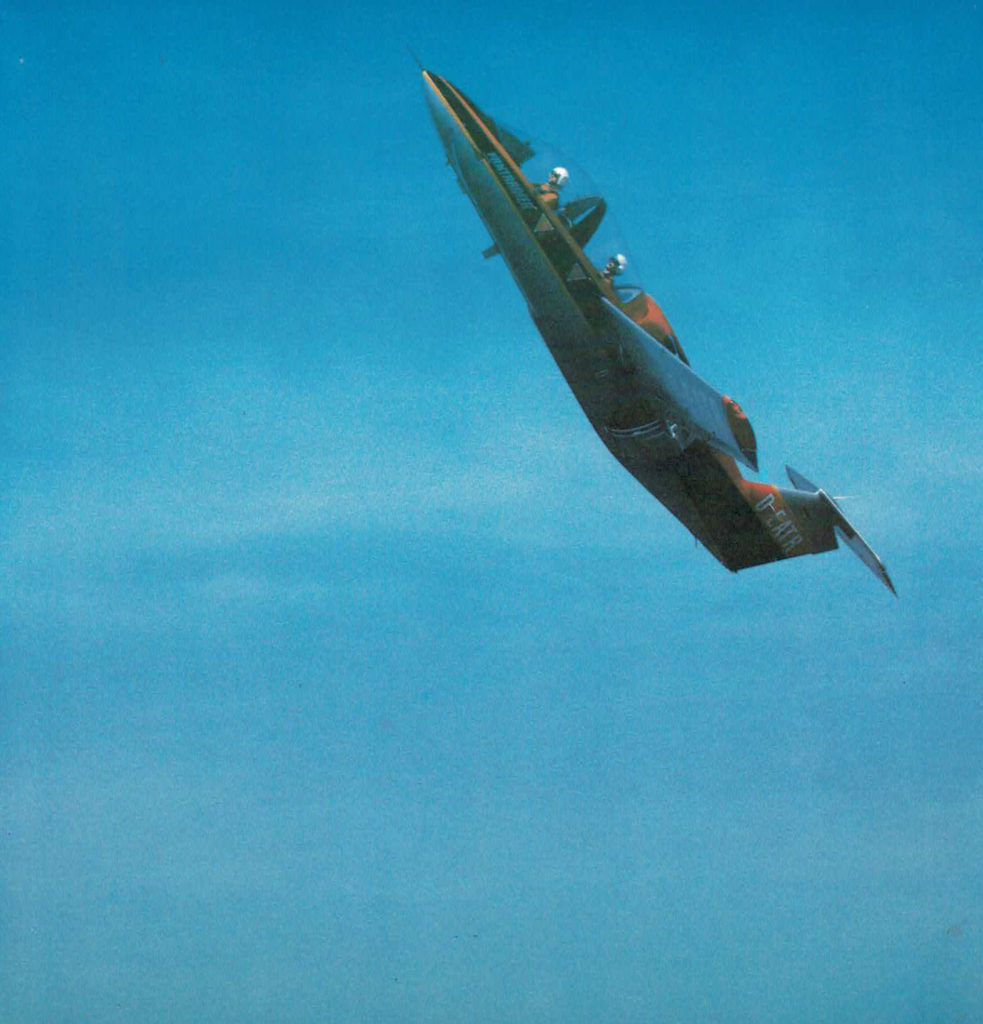

The Fanjet 600 is an excellent military & civil training aircraft. It is capable of performing all typical military, acrobatic and UPRT (Upset Recovery Training) maneuvers. Furtermore it is a high performance machine for ambitious private pilots.

Fact is, that several outstanding aircraft being built in the 1980’s/ 1990’s have been discontinued.

However, the aerodynamics have not changed, except major advances

in avionics with the introduction of glass cockpits.

FanJet Aviation believes that some “older designs” being modernized

by glass cockpits, are very valid for pilot training and are an

excellent option today due to their attractive purchase prices.

FANJET HISTORY

When, at the beginning of the 1970s, many air forces realised that advanced pilot training would become significantly more expensive due to new, technologically advanced systems, they looked for an alternative that would offer the flight characteristics of a jet aircraft on the one hand and the low costs of a propeller-driven aircraft on the other.

The aircraft construction company Rhein-Flugzeugbau in Mönchengladbach had already gained extensive experience in the application of jacketed propeller drives at the end of the sixties. Using the jacketed propeller test vehicle RFB Sirius, Hanno Fischer was able to demonstrate the jet-like behaviour of an aircraft operated with a jacketed propeller located in the fuselage behind the cockpit as early as 1968. At the ILA 1970 Rhein-Flugzeugbau presented to the public for the first time project sketches of a civil passenger aircraft and a military trainer powered by a jacketed propeller. This first Fantrainer design, like the Sirius I which was being tested at the time, still had a low-lying tailplane. The civil and military aircraft differed only in the cockpit section in front of the jacketed propeller, which was to be interchangeable in order to be able to adapt this part to the respective target pattern as quickly as possible in the future.

Since the Luftwaffe showed no interest in the development in 1970, Rhein-Flugzeugbau, after completion of the Sirius trials and with the support of the state of North Rhine-Westphalia, began developing the civil variant in 1972 under the name Rhein-Flugzeugbau Fanliner. Only after its successful maiden flight in 1973 did the German Air Force show interest in testing the military variant as a successor to the Piaggio P.149. In March 1975 Rhein-Flugzeugbau received an order from the Federal Ministry of Defence to build two prototypes of the military Fanliner

Further developments

After the FT-600 fan trainer had proven to be underpowered for some tenders, a number of more motorized fan trainer designs had been planned at Rhein-Flugzeugbau since the mid-1980s. The FT-800 , FT-1000, FT-1200 and FT-1500 have become known. The FT-1000 was especially designed as a weapon carrier for a request from Paraguay.

At the beginning of the nineties, the design of the Rhein-Flugzeugbau Tiro-Trainer was created by Rhein-Flugzeugbau under Christoph Fischer. It was to be equipped with a Williams Rolls-Royce FJ44 engine and used modern jacket screw technology, which Hanno Fischer had developed in the late 1980s as part of Whisperfan technology. It was still offered to the Thai Air Force in 1994 as a replacement for the RTAF fan trainer. After leaving the DASA consortium, Rhein-Flugzeugbau had no funds left to implement the design.

Testing and further development (1977-1979)

On October 27, 1977 RFB test pilot Göbbels took off with the Wankel engine-driven AWI-2 prototype D-EATJ, later temporarily 98 + 30 in Mönchengladbach for the first flight. The turbine-driven second prototype ATI-2 D-EATI flew for the first time a few days before the start of the Bundeswehr test program on May 31, 1978. Both aircraft were handed over to the Luftwaffe test site 61 in Manching in June 1978, where the comparison flight with the Beech T-34C Turbo Mentor and the Swiss Pilatus PC-7 took place. When the ATI-2 crashed on a transfer flight from Manching to the Farnborough airshow in bad weather in September 1978, the AWI-2 D-EATJ was converted to the Allison turbine, as a preliminary decision between the two models had already been made in favor of the turbine-powered aircraft. The ATI-2 wins the comparison flying. The Wehrbeschaffungsamt then began negotiations on the construction of 30 ATI-2 units with Rhein-Flugzeugbau in July 1979. The negotiations ended in September 1979, however, after the Air Force decided to continue operating the Piaggio P.149 until 1984 for cost reasons.

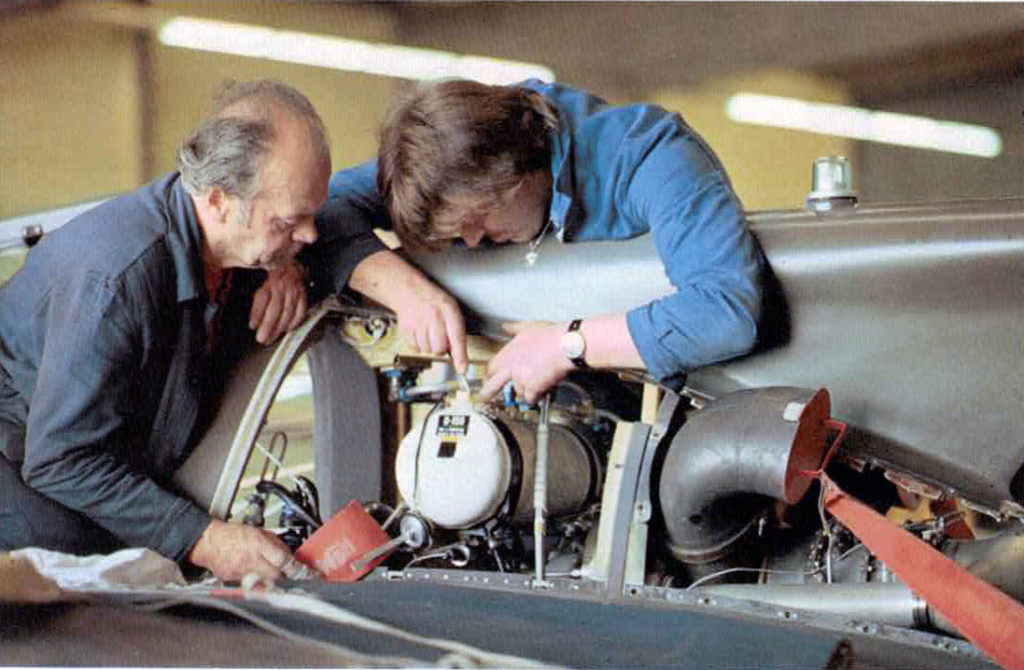

During the air force test, Hanno Fischer already received feedback from the flight test as the basis for the further development of the fan trainer. Fischer met the demand for a more motorized variant of the fan trainer in 1979 by installing the more powerful C30 variant of the Allison turbine with 600 hp. The cabin fuselage was also lengthened and increased somewhat due to the feedback from the Bundeswehr’s testing program. This new variant of the fan trainer was called the FT-600 fan trainer from 1980, while the fan trainer with the original C20 variant and modified fuselage was called the FT-400.

The ATI-2 prototype was converted to the C30 variant, but was given a reduction gear. The cabin modifications were initially not implemented in the prototype. In the end FT-400 and FT-600 had the same design when production for the RTAF (Royal Thai Air Force) started.

USAF Next Generation Trainer (NGT) Call (1980)

After the successful completion of the Fantrainer test by the German Federal Air Force, the U.S. Air Force and the U.S. Navy were also interested in the Fantrainer as a successor to the Cessna T-37B in the summer of 1979, for which up to 600 units were needed. Rhein-Flugzeugbau participated in the NGT tender with its partner Vought in 1980. The cockpit section of the Fantrainer design FT-600 was replaced by a variant with two seats arranged side by side. The plastic wings of the Fantrainer were exchanged for metal wings, as Vought had no experience in processing GRP components. In addition, the C30 variant of the single Allison turbine was exchanged for two coupled C20 variants to meet the requirement of two engines in the tender. The design was submitted in April 1980 as the Vought V.538 Eaglet from Vought Corporation and was approved for the study phase by the Tender Commission with four competing designs from Cessna, Fairchild, General Dynamics and Rockwell. In the subsequent study phase, Vought changed the layout of the V.538 significantly. The sheathing screw integrated into the fuselage is exchanged for two sheathed fans on the fuselage. The stern area was enlarged and boarded up. However, the new design Vought V.539 Eaglet proved to be too heavy to meet the NGT requirements. The Vought design withdrew from the NGT tender in October 1980. The winner of the NGT tender was the Fairchild T-46.

Deployment with the Thai Air Force (1982-1994)

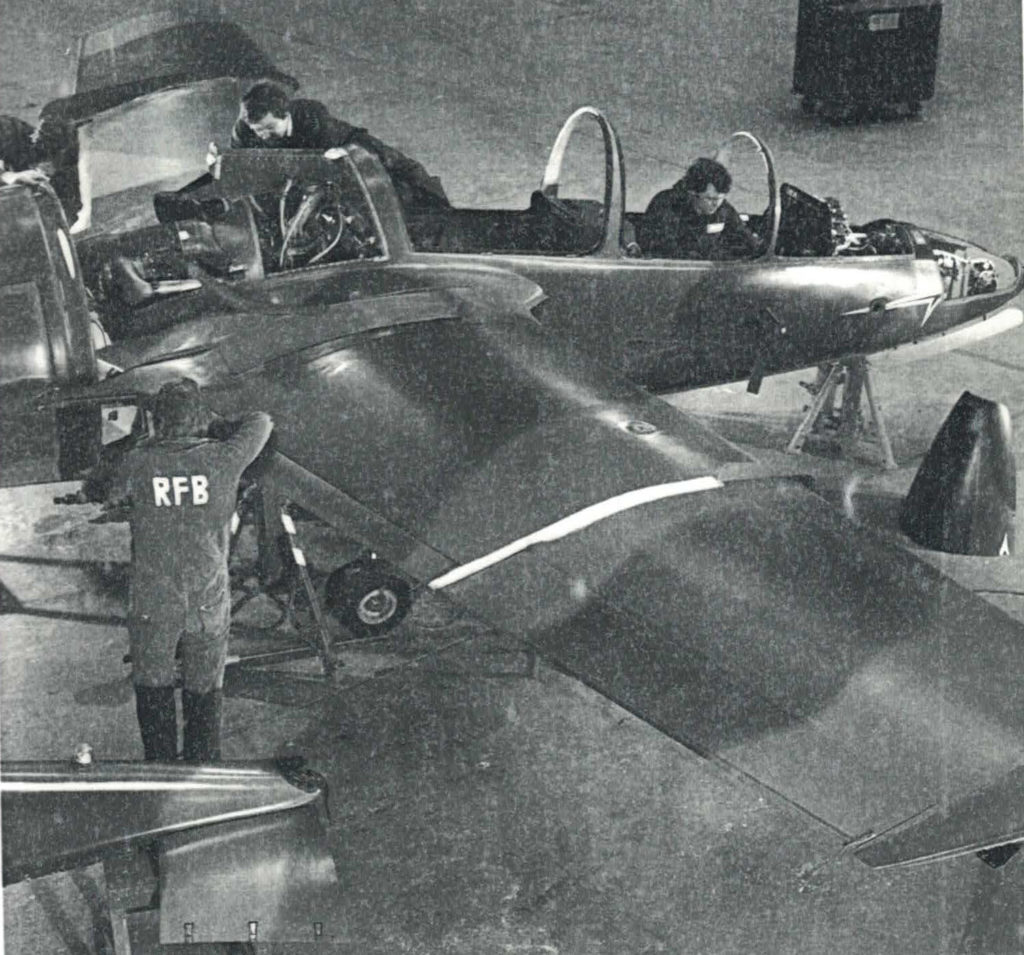

In Thailand, the Science and Weapon Systems Development Center of the Thai Air Force had been working since 1976 on the development of an RTAF-5 trainer aircraft based on a downsized OV-10 Bronco with pressurized propeller propulsion. In order not to delay the introduction of the F-5E Tiger in the Thai Air Force, the use of the Fantrainer was investigated in Thailand in 1980. In August 1982 the Thai Air Force ordered 16 Fantrainer FT-600 and 32 Fantrainer FT-400 from Rhein-Flugzeugbau. In addition, RTAF drew 26 options for further FT-600 Fantrainers. In deviation from the design of the FT-400/600, the Thai Fantrainer received a cockpit adapted to the F-5 with ejection seats, which were developed at Rhein-Flugzeugbau. Only the production of assemblies at Rhein-Flugzeugbau in Germany was planned. The final assembly of the machines was to take place at SWSDC in Thailand. In order to extend the experience in aircraft construction at SWSDC, new metal wings for the FT-400 of SWSDC should be designed with the help of RFB and later manufactured in Thailand. The FT-600 kept their plastic wings from German production. The first two FT-400 and FT-600 were to be built in Germany at Rhein-Flugzeugbau as sample machines.

On August 12, 1984 the FT-600 prototype D-EATR took off for its maiden flight in Mönchengladbach. The three other prototype aircraft followed in the same month. After completion of the pilot training in Mönchengladbach, two sample aircraft (D-EIWG, D-EIWK) were disassembled and shipped to Thailand. The other two sample machines remained in Germany for component production at Rhein-Flugzeugbau. At the same time, the shipment of the first assembly kits to Thailand began. The final assembly of the first FT-600 started in 1986. 14 units were delivered to the training associations as B.F.18k by the end of 1987. Due to delays in the development of the metal wings the final assembly of the first FT-400s did not start until 1988. They were used as B.F.18s by the training associations. However, the metal wings proved to be too heavy and inaccurate in production. After the assembly of 11 Fantrainer FT-400 the assembly line in Thailand was stopped in 1992. After the insolvency of Rhein-Flugzeugbau in 1994 the Fantrainer were taken out of service and stored by the Thai Air Force.

Second selection process in Germany (1985–1987)

The interest in Germany awakened again in the mid-1980s, as the Luftwaffe was meanwhile looking for a successor model for the Piaggio P.149. Between July and September 1985, both the 400 and 600 models underwent extensive testing, but the German Ministry of Defence again decided against the Fantrainer. The military jet pilot training was subsequently completely transferred to the USA in 1987.

In order to be able to carry out pilot retraining in Germany, the Air Force in 1989 decided to purchase two low-cost airborne simulators based on the Fantrainer and included them in the 1990 budget. Due to the changed world political situation, the Ministry of Defence was no longer able to sufficiently justify the need in 1990 at the budget committee meetings and finally decided to refrain from procuring the two fan trainers in January 1992.

USAF Joint Primary Aircraft Training System (JPATS) (1990)

The former RFB parent company MBB participated in the JPATS tender for a trainer aircraft, which was reissued in the USA in 1989. The MBB Group commissioned its subsidiary Rhein-Flugzeugbau, for which Christoph Fischer had meanwhile taken over the technical management, with the development. Under the name Fanranger Christoph Fischer used the rear metal fuselage of the Fantrainer and designed the front fuselage section completely in GRP construction. The Fanranger was considerably larger than the original Fantrainer and was powered by a P&W JT15D-5C Turbofan engine. After Rhein-Flugzeugbau was sold to ABS International, the development and construction of the first assemblies were still carried out in Mönchengladbach. However, the remaining work was then relocated to Manching and completed together with the American partner Rockwell. The Fanranger, later also Rockwell Ranger 2000, was defeated in the JPATS tender of the Raytheon MkII.

Construction

Hanno Fischer used the already existing Fanliner I as the starting pattern for the military fan trainer. Instead of the sports plane cockpit, the fan trainer was given a cockpit section based on the Alphajet used as an ascent pattern by the Air Force. The rear with the jack screw drive was taken over by the fanliner including the Wankel engine. Since the wings of the fanliner taken over by Grumman Yankee did not allow jet-like behavior, Fischer decided to use the negatively swept plastic wings from the LFU-205 development by Leichtflugtechnik Union GmbH. As with Hanno Fischer’s Rheinflug RW-3, two wing variants were planned. For the beginner training, the fan trainer should be equipped with longer wings, while the advanced training should take place with short, aerobatic surfaces. The required retractable undercarriage was developed by Gomolzig.

Compared to these “pure-bred” propeller aircraft, the fan trainer offered a completely new concept: a small, jet-like fuselage had a jacketed propeller behind the cockpit, the drive of which was located in the center of gravity of the aircraft and thus gave it a jet-like load ratio. In addition, the rotor blades were adjustable, which also accommodated the flight behavior of a jet.

When the end of NSU Wankel engine production was still in the offering during the development of the fan trainer, Hanno Fischer proposed the construction of the second prototype with a Lycoming LTS-101 turbine engine. However, the Bundeswehr chose the Allison 250 C20 turbine used in the Boelkow Bo 105.

While the fan trainer operated with a Wankel engine was designated AWI-2, the turbine-driven fan trainer was given the designation ATI-2 (A = initial trainer, W = Wankel / T = turbine / I = integrated jacket screw / 2 = two-seat). Hanno Fischer also proposed a four-seater variant AWI-4 or ATI-4 as a replacement for the four-seater Piaggio. The ATI-2KI with a shortened wing area of 7.88 m was to be used as an aerobatic advanced trainer.

FANJET NEXT GENERATION 2010

In 2010 the company Fanjet Aviation GmbH picked up on the recipe for success from the 1970s and acquired construction, construction and test documents as well as the approval documents in order to re-initiate the production of the former “Fan Trainer”.

Read more under ´NEWS´.